![]()

Refrigerated Base worktops

Dozens of models and configurations are available including self-contained solutions with mega, dual rail and more.

Pizza Prep Tables

Preparing pizzas has never been more convenient or efficient with Delfield’s complete line of Pizza Prep stations. Available in a variety of sizes and configurations, Delfield makes pizza prep fast and easy!

Dual Rail Prep Tables

Choose from either the F18PD48 or F18PD72 dual rail prep stations with flush mount LiquiTec® Raised Rails.

Compact Worktops

Looking to take advantage of a little space and turn it into a productivity center – look no further than these compact worktops by Delfield.

Flat Top Refrigerated Stations

Delfield’s 4400 series flat-top stations are an industry standard for quality, efficiency and reliability. All the 4400 series are front-breathing which allows the unit to sit right against a wall for extra space.

Refrigerated Salad Tops

Featuring Delfield’s 4400 series with the patented air screen which keeps the product cold – without drying it out. Also, find a complete selection of Delfield’s deep self-contained mega-top and regular-top salad tables.

Refrigerated Mega Tops

Delfield’s 4400 series mega top stations are an industry standard for quality, efficiency and reliability. All the 4400 series are front-breathing which allows the unit to sit right against a wall for extra space.

Flat Top Freezer Base

Two models to choose from, both from Delfield’s 4400 series. The 4400 series features front breathing which allows for the counters to be placed directly up against a wall, saving space.

Freezer Base Worktops

Whether you’re looking for a freezer base with a flat top – or looking to save space by installing a freezer base for use as an equipment stand, you’ll find it here.

![]()

Counter Mixers

From the 5 quart Teddy – commercial grade countertop mixer – right up to 3 additional models that are perfectly balanced for everything from pizza to pretzels and everything in between. When you’re looking for a full-strength mixing, beating, and stirring solution in a convenient countertop size – trust Varimixer.

Floor Mixers

From 30 to 150 quarts – Varimixer has the right-sized mixer for your operation. Varimixers are built with only the best components so a mixer can keep up and last. Featuring belt drive technology and all stainless steel construction, Varimixer really is the – Vari-best choice for your operation.

Accessories

When you compare Varimixers accessories to the competition you start to see what sets Varimixer apart. Smart design, robust construction. See the full line of floor and counter mixer accessories here

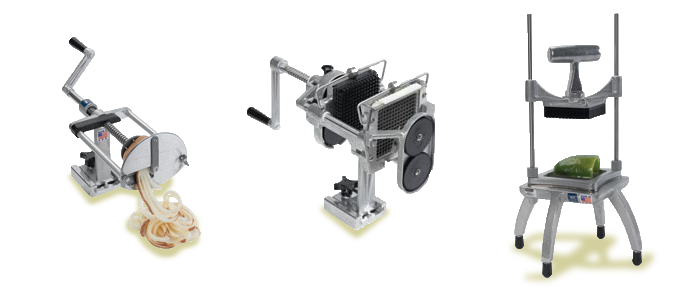

Food Preparation Equipment

Built tough and engineered to perform better, NEMCO products afford fast and easy slicing, dicing, wedging, cubing, coring and chopping by even your least experienced employees. With NEMCO, you keep better control of the shape, size, freshness and appearance of every serving.

Consistent food quality.

No matter who’s in your kitchen, every cut is the same – every time, everywhere – so your customers always get the great taste and quality they expect.

Greater portion control.

Consistently sized food product allows consistent, error-free portioning and measuring. If your recipe requires three 1/4-inch tomato slices, that is exactly what you’ll get with NEMCO. No more. No less.

Reduced food waste.

NEMCO products use food efficiently. They cut the entire food item, from end to end. There’s no incomplete processing – no “oversized” scraps. Less food gets thrown out, so your food costs can go down.

Improved operator comfort.

NEMCO products are carefully engineered and evaluated to make users more effective and efficient on the job. Every motion, and every repetition are considered during product development to make food preparation as fast, easy and fatigue-free as possible. Special safety features are built in too.

Superior durability.

NEMCO products are designed and built to stand up to the most rigorous demands. Yet they are light enough for easy cleaning and compact enough to store. Superior engineering combined with durable cast aluminum, rust-resistant stainless steel and engineered plastics afford long life and easy maintenance.

Food Preparation Equipment

Slice, grind, mix, or chop – look to Vollrath for all of your Food Preparation needs. Find all the features and functions you need in the greatest value lines available.

Omcan Since 1975

Omcan has been providing its customers with diverse, dependable and proven products for over 30 years.

![]()

About Bizerba USA

Bizerba is a worldwide leader in manufacturing retail scales, slicers, weigh price labeling equipment as well as checkweighers, industrial scales and software.

A manufacturer founded in 1866 with approximately 2600 employees worldwide, Bizerba is active in each of the world’s key economic regions, in many cases as the market leader exporting to over 120 countries.

Bizerba USA, Inc. was incorporated in 1984 as a subsidiary of the parent company Bizerba GmbH & CO KG (Germany).

The Bizerba corporate office is located in Piscataway, NJ. We are working with factory-authorized distributors in all 50 states and Puerto Rico.

Foodservice

Imagine being able to trust one manufacturer for over 75% of your kitchen! Advance Tabco makes everything including sinks, work tables, dishwashing tables, cabinets, chef counters, shelving, aluminum racks, and more. Rest assured knowing that your project is in the hands of one of the most trusted and recognized names in the industry.

Precise, easy, durable, reliable

Globe’s dedication to quality manufacturing, exceptional service, and value is well known. Not only for their broad slicer and mixer selections, but also for their expanded line of countertop grills, fryers, cookers and scales.

![]()

High-Quality Bakery Equipment & Meal Packaging Systems

Oliver Packaging & Equipment Company is a Grand Rapids, Michigan-based company that has been developing and manufacturing innovative solutions for diverse markets since 1890.

Oliver Packaging & Equipment Company has a long and evolved history in equipment manufacturing and innovative packaging solutions. Originally started as a woodworking equipment company, this expertise with blades set the stage for the introduction of the first bread slicer in 1932. By 1944, a line of wrapping and labeling equipment complimented the bread slicers, launching Oliver into packaging system solutions.

Tradition

Since the introduction of the first bread slicer in 1932, Oliver has been providing quality equipment and unmatched customer service to bakeries, supermarkets, restaurants, and delis. It’s been said that you don’t own a bread slicer, you own an Oliver. This tradition of quality-built equipment is evidenced in our full line of bakery equipment – from bread slicers to ovens to Panini grilles – the tradition continues.

Innovation

Building on the foundation of quality equipment design and manufacturing, Oliver’s packaging equipment – the Speedseal™ Fresh Pack Systems – provides reliable and affordable solutions for packaging needs from small-volume applications to high speed customized equipment. Systems are available for small-volume programs as well as high-speed, food processing applications.

![]()

About Robot Coupe

For over 30 years Robot Coupe U.S.A. has made the metro Jackson, Mississippi area its home. Throughout these years, Robot Coupe has been the food service industry leader in the development and refinement of commercial food processors and vegetable preparation units.

Robot Coupe U.S.A. was founded by Jackson residents Rollins Brown, Bill Gilmore and Dan Bounds. After seeing the Robot Coupe food processor in action at LeRuth’s Restaurant in New Orleans, the three partners in conjunction with Robot Coupe France established a new company, Robot Coupe U.S.A., to market this amazing new product to the American market. When the Robot Coupe commercial food processor was developed, it was a totally new concept since food preparation-slicing, dicing, shredding, and grating-was done by hand making it very labor intensive. Robot Coupe U.S.A. introduced and promoted the commercial food processor to the North American continent by demonstrating it at various shows, seminars, and conventions throughout the country and made the name Robot Coupe synonymous with commercial food processors.

Because of the company’s dedication to producing the very best product available, its commitment to research and development, and its constant striving to give its customers the best customer and service support available, the Robot Coupe Commercial Food Processor has become the worldwide “standard of the industry” for the entire food processing industry-restaurants, schools, correction facilities, hospitals, nursing homes, cruise ships, and delicatessens.

The company has become the food service industry leader in the development and refinement of food processors, vegetable preparation units, and combination processing units. In 1998 Robot Coupe introduced the “Blixer”—a combination food processor/blender in one machine. This machine enabled the healthcare industry to serve the same foods to everyone in their facility by processing any food for patients with modified diet needs down to tube feedings, if needed, without the loss of any valuable nutrients. For gourmet chefs, the Blixer produces the smoothest and creamiest of purees and patés in just seconds.

The latest product introduction is the Power Mixers line, which is distinguished from its competition by its superior cleanability, power, ease of use and enhanced sanitation.

Over the years, Robot Coupe has been honored many times for its superior products and excellent customer service. Recently Robot Coupe was named “Best in Class” in the food processor category by an independent panel of industry equipment dealers, broadliners, and consultants.

![]()

About Piper Products

Piper Products doors opened in Cudahy, WI in 1960. As a small company catering to the needs of local, independently owned bakeries and grocery stores, Piper started by primarily supplying bread racks and food transport cabinets. As the business grew and industry contacts were made and fostered, the desire for expansion demanded that Piper look for more ways to support their growing client base.

In 1990, Piper bought Super Systems, a company out of Green Bay, WI, which offered a quality line of ovens and proofers that could accommodate any baking need. That same year, Piper closed the Cudahy, WI facility and moved operations to Wausau, WI.

To expand the product line, Piper purchased three companies between 2000 and 2006, SECO Products Corp., Servolift, and Chef System, an extensive line of Cook & Hold Cabinets. With product and distribution lines Piper hadn’t already had, SECO’s Elite and Reflections cafeteria and buffet serving systems were exactly the direction Piper was anxious to head in. Expanding their presence in schools, hospitals, and prisons, SECO’s premier line of cafeteria and buffet serving equipment was the perfect addition to Piper’s quickly growing lineup.

In 2013, Piper purchased R&D Fixtures out of Tennessee. R&D Fixtures, already well known in the grocery and convenience store market as manufacturers of customizable ready-to-eat food merchandising equipment, has been an exciting asset to their existing line of refrigerated and heated food merchandisers.

Piper Products is focused on providing quality products, unparalleled service, and optimum value.